-

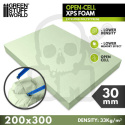

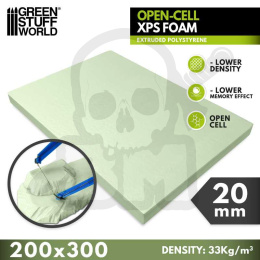

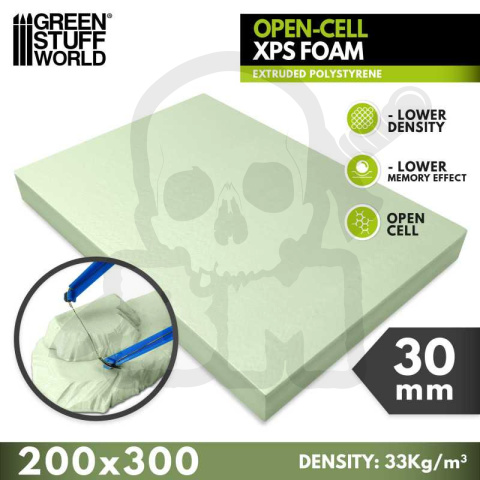

Open-cell extruded polystyrene XPS Foam 30mm 200x300mm 1 szt.

| Shipping within | 24 hours |

| Shipping price | The Lack Of |

| The Availability Of |

|

Open-cell extruded polystyrene XPS Foam 30mm 200x300mm 1 szt.

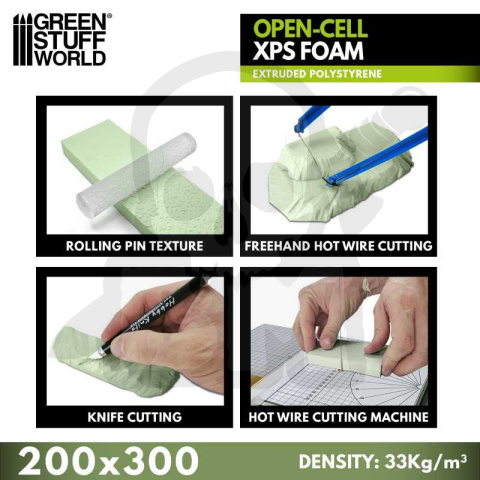

Open-cell XPS extruded polystyrene foam, also called Styrofoam, is a lightweight, strong, durable, and less dense material than its sister closed-cell XPS foam in blue, giving it a "low memory" effect that is ideal for marking, engraving, texture transfer, scratching, and roughing. Open-Cell XPS Foam can be used to create various scenery such as hills and cliffs, game boards, different model building elements such as bricks, or even columns and large bases for dioramas. It is a lightweight and durable material that is easy to work with, making it a popular choice among amateurs and professionals.

The texture to the touch of this material is reminiscent of very fine sandpaper, so for painting, it is recommended to post-process it by applying a protective coating or surface sealer such as our Medium Decoupage. Unlike blue XPS foam, this open-cell material can be engraved with textured rollers or carved with a modeling tool for sculpting.

Open-cell extruded XPS also has great moisture resistance and works very well as a thermal insulator. This makes it an excellent choice for creating terrains, landscapes, and other modeling elements, such as buildings, bases, and bricks, as well as being ideal for making game boards, dioramas, and other craft projects.

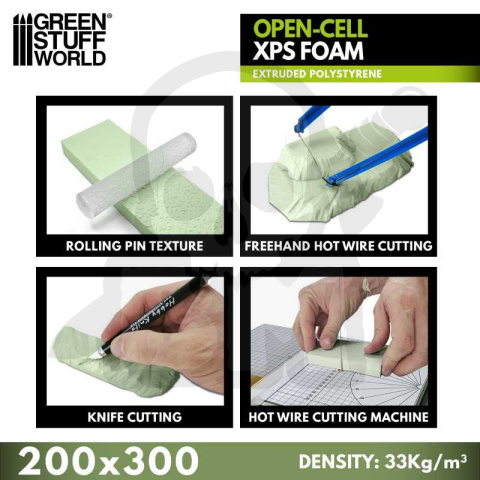

There are several tools you can use to shape and cut it. One of the most common tools is a hot-wire cutter, which is a handheld device that heats a wire to cut through the foam. A hot knife is another tool that uses heat to cut through the foam, but it is more precise than a hot-wire cutter and is ideal for creating intricate details.

Saws and knives can also be used to cut through this material. A hand saw or jigsaw is ideal for cutting through larger pieces of foam, while a sharp utility knife or craft knife can be used to make smaller cuts and details.

When working with this material, it is essential to take safety precautions as this material can release toxic fumes when heated or sanded vigorously. It is important to wear a fume mask or work in a well-ventilated area to avoid inhaling the fumes.

- Content: 200x300mm

- Thickness: 30 mm

- Type: Open-cell

- Estimated Density: 33 kg/m³

WARNINGS:

- Extruded polystyrene XPS is capable of giving off toxic fumes when heated. That heating can be achieved when hot-wire cutting, vigorously sanding, and also by application of hot glue.

- This foam should never be worked in an enclosed environment or without wearing a graded fume mask. Cutting styrofoam with an electric saw will also melt and produce fumes.

- Always use appropriate glue such as tuft glue or hot glue to stick styrofoam together.

- Standard PVA glue or white glue will only stick this foam where they have contact with the air, where air cannot reach the glue then the glue will NOT set and remain liquid.

- Dust produced when sanding or cutting styrofoams with a saw is also hazardous and should be avoided by wearing a dust mask and using appropriate ventilation and other safety measures.

- The safe maximum use temperature of extruded polystyrene foam XPS is 75 degrees Celsius (167º Fahrenheit).

- Manufacturers

![[{[item.product.name]}]]([{[item.product.photo.url]}] 125w)